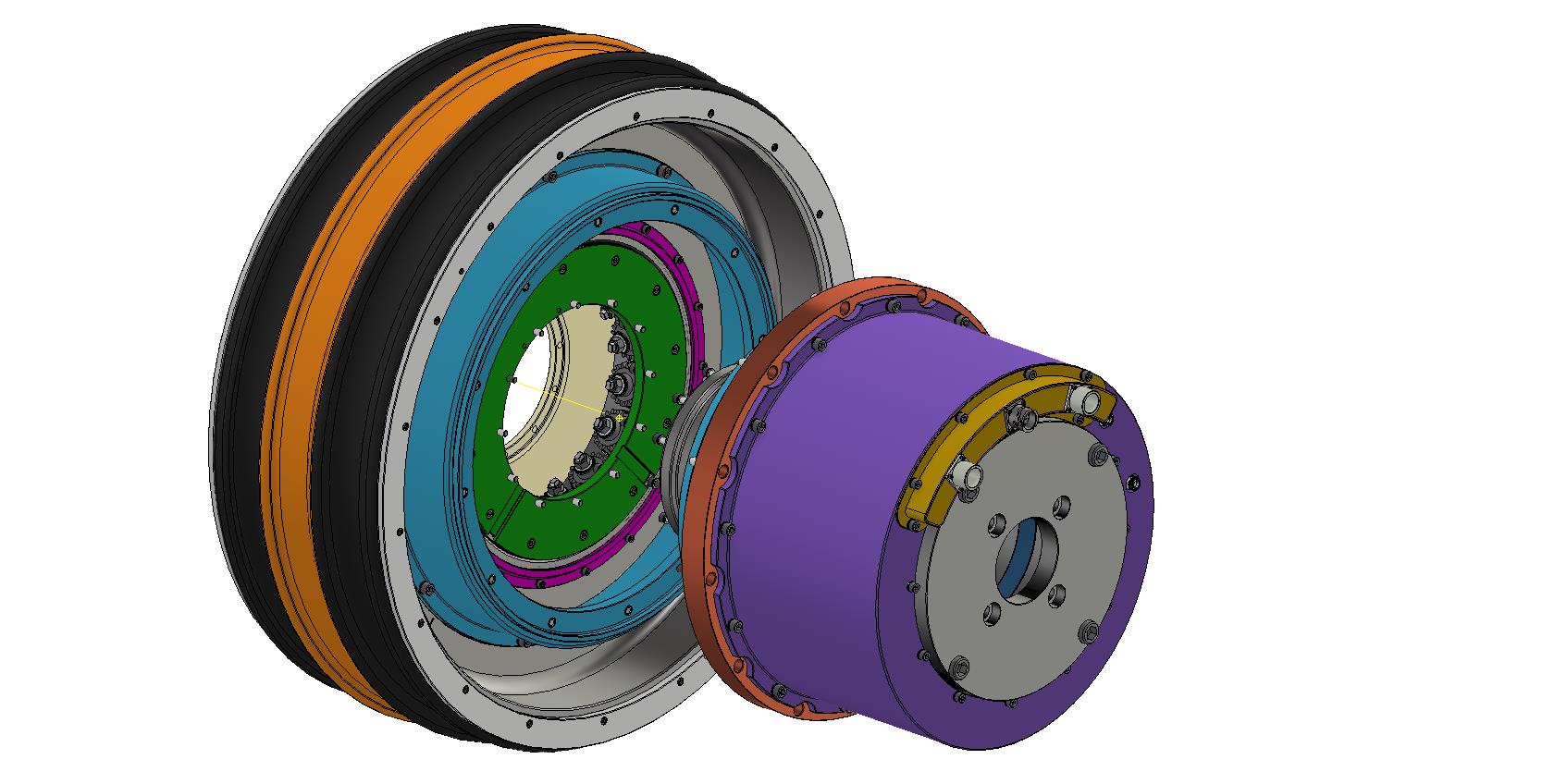

Marangoni Meccanica has developed a patented system to automate loading and unloading operations for carcasses and green tires, meeting the demand for integrated production lines. This tooling is designed to provide precise control over flange diameters, even during shaped carcass rotation, with synchronized or independent movement of inboard and outboard flanges.

During the engineering phase of the system, key considerations included user-friendliness, easy maintainability, and safety features, such as holding brakes engaged during manual operations. The system utilizes electronic control, which is designed to enable the adjustment of bead lock force, adaptable during the cycle according to recipe requirements. This facilitates fluid expansion and contraction movements, preventing surface damage to the bead area.

Stefano Roselli, technical director at Marangoni Meccanica, explained that the possibility to define the bead lock force according to recipe allows the user to always apply the correct force without disrupting the material. The possibility to control force and the position of the bead lock saddle allows an increase in the adaptability of the system. This causes a less precise positioning of the carcass during loading, without prejudice to the bead centering precision and air leakage during inflation.

Francesco Motta, CEO of Marangoni Meccanica said “Marangoni Meccanica has been taking part in this event since its very beginning. TTX has always offered a fresh perspective about innovations in tire industry for exhibitors and visitors alike.” He added that “The show opens doors to exciting new business opportunities and facilitates meaningful connections.” Visitors can see this electromechanical bead lock system in action at Booth 8040.